|

Assembled Roving for GMT |  |

Assembled Roving for SMC |

|

Assembled Roving for Filament Winding |

|

Assembled Roving for Chopping |

|

Assembled Roving for CSM |  |

Assembled Roving for Centrifugal Casting |

|

Assembled Roving for Spray-up |  |

Assembled Panel Roving |

|

Direct Roving for LFT |  |

Direct Roving for Weaving |

|

Direct Roving for Filament winding |  |

Direct Roving for Pultrusion |

|

Chopped Strand for Thermoplastic |

|

Chopped Strand for BMC |

|

E-Glass Emulsion Chopped Strand Mat |

|

E-Glass Powder Chopped Strand Mat |

|

Wet Chopped Strands |  |

E-Glass Texturized Roving |

|

Woven Roving |  |

High performance Compofil TM |

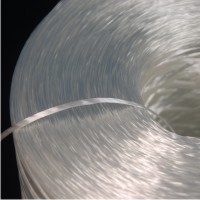

Assembled Roving for GMT

E-Glass Assembled Roving for GMT is based on special sizing formulation, compatible with modified PP resin.

Its features as follows:

- moderate fiber stiffness,

- excellent ribbonization and dispersion in resin,

- excellent mechanical and electrical property.

The GMT sheet is a kind of structural material, widely used in the sector of automotive, building & construction, packing, electrical equipment, chemical industry and sport.

| Product No. |

Filament Diameter (μm) |

Resin Compatibility |

Applications | Data sheet |

|---|---|---|---|---|

| 522 | 13 | PP | Roving for GMT-RD, delivering excellent dispersion after chopping, and mechanical property | Download |

Assembled Roving for SMC

Assembled Roving for SMC is compatible with unsaturated polyester, vinyl ester resin, delivering good dispersion after chopping, low fuzz, fast wet out and low static.

Its end use applications cover:

- Automotive parts: bumper, rear cover box, car door, headliner;

- Building & construction industry: SMC door, chair, sanitary ware, water tank, ceiling;

- Electronic & electrical industry: a variety of parts.

- In recreation industry: a variety of apparatus.

| Product No. |

Tex | Product Features | Resin Compatibility |

Applications | Data sheet |

|---|---|---|---|---|---|

| 440 | 2400、 4392、 4800 |

Mainly for structural SMC product and general pigmentable SMC product | Unsaturated polyester, vinyl ester resin | Truck parts, water tanks, door sheet and electrical parts | Download |

| 442 | 2400、 4392、 4800 |

Mainly for pigmentable SMC product with high surface quality; Low combustible content; Suitable for Asian market | Unsaturated polyester, vinyl ester resin | Ceiling tiles, door sheet | Download |

| 410 | 2400、 4392、 4800 |

Excellent hydrolysis resistance, mainly for manufacture of SMC bathroom equipment; Suitable for Asian market | Unsaturated polyester, vinyl ester resin | Bathtub | Download |

| 456B | 2400、 4392、 4800 |

Good mold flow; High strength; Suitable for manufacture of Class A SMC product | Unsaturated polyester, vinyl ester resin | Exterior body parts of high-end automotive and truck markets | Download |

| 458A | 2400、 4392、 4800 |

Mainly used for manufacturing pigmentable SMC product with high surface quality; High combustible content, enabling high line speeds and heavy density sheet production; Mainly for North American market | Unsaturated polyester, vinyl ester resin | Bathroom equipment | Download |

| 440A | 2400、 4392、 4800 |

Good choppability and excellent dispersion after chopping; Low static | Unsaturated polyester, vinyl ester resin | Automotive bumper and headliner | Download |

Assembled Roving for Filament Winding

Assembled Roving for Filament Winding is specially designed for FRP filament winding process, compatible with unsaturated polyester.

Its final composite product delivers excellent mechanical property, and is mainly used to manufacture storage vessels and pipes in petroleum, chemical and mining industries.

| Product No. | Resin Compatibility | Product Features | Applications | Data sheet |

|---|---|---|---|---|

| 266 | UP | Fast wet out, low fuzz and high strength | pipeline | Download |

Assembled Roving for Chopping

162 Assembled Roving for Chopping is coated with special silane-based sizing, compatible with UP and VE, delivering relatively high resin absorbability and excellent choppability, while its final composite products deliver superior water resistance and excellent chemical corrosion resistance. It is typically used to manufacture FRP pipes.

| Product No. |

Resin Compatibility |

Product Features | Applications | Data sheet |

|---|---|---|---|---|

| 162 | UP, VE | Good dispersion; Moderate wet out in resin; Good static control and good choppability | Used in manufacture | Download |

Assembled Roving for CSM

Assembled Roving for CSM

| Product No. |

Nominal Linear Density, tex |

Product Features | Resin Compatibility |

Applications | Data sheet |

|---|---|---|---|---|---|

| 512 | 2400 | General purpose roving; Good dispersion after chopping; Good static control and fast wet out in resins | Unsaturated polyester, vinyl ester and epoxy resins | Used to manufacture general CSM | Download |

| 516 | 2400 | Roving for low grammage chopped strands mat; Extremely low linear density, delivering excellent static control and good dispersion after chopping | Unsaturated polyester, vinyl ester and epoxy resin | Used to manufacture low grammage chopped strands mat | Download |

| 518 | 2400 | Relatively high fiber stiffness; Good dispersion after chopping; Excellent static control; Moderate wet out in resin | Unsaturated polyester, vinyl ester and epoxy resin | Suitable to manufacture chopped strands mat with moderate bonding with resin | Download |

| 528 | 2400 | Good dispersion after chopping,Good anti-static property,Excellent wet-out,Good refractive index matching between resin and glass fiber,Excellent echanical properties of composite parts | unsaturated polyester | 528 delivers light weight, high strength and high impact strength, and is designed to manufacture transparent panels. | Download |

Assembled Roving for Centrifugal Casting

Assembled Roving for Centrifugal Casting is coated with silane-based sizing, compatible with UP resin, delivering excellent choppability and dispersion, low static , fast wet out, and excellent mechanical properties of the composite products.

| Product No. |

Nominal Linear Density, tex |

Product Features | Resin Compatibility |

Applications | Data sheet |

|---|---|---|---|---|---|

| 622 | 2400、4800 | Fast wet out, extremely low resin absorbability, high strength of the composite product; designed for the European market | Unsaturated polyester | Centrifugal casting pipe | Download |

Assembled Roving for Spray-up

Assembled Roving for spray-up is compatible with UP and VE resins.

It delivers properties of low static, excellent dispersion, and good wet out in resins.

It covers a wide range of applications: bathtub, FRP boat hulls, various pipes, storage vessels and cooling towers.

| Product No. |

Linear Density, tex |

Product Features | Resin Compatibility |

Applications | Data sheet |

|---|---|---|---|---|---|

| 172 | 2400、3460、4800 | Fast wet out, easy roll-out, no spring-back in sharp corner, optimum dispersion after chopping, few fiber swap | Unsaturated polyester, vinyl ester resin | Bathtub, supporting components | Download |

| 178 | 2400、3460、4800 | Easy to operate in spraying-up process, easy roll-out, no spring-back in sharp corner, designed for high speed robotic spray-up process | Unsaturated polyester, vinyl ester resin | Bathroom equipment, yacht components | Download |

| 180 | 2400、3460、4800 | Fast wet out ensuring optimum air release, excellent mechanical and water resistance property of the finished product | Unsaturated polyester, vinyl ester and polyurethane resin | Bathtub, FRP boat hull | Download |

| 170 | 2400、3460、4800 | Moderate wet out speed, ideal for product with large vertical surface | Unsaturated polyester, vinyl ester resin | Swimming pool, bathtub | Download |

Assembled Panel Roving

Assembled Panel Roving is coated with a silane-based sizing compatible with UP. It can wet out fast in resin and deliver excellent dispersion after chopping.

The panel made from it delivers properties:

- light weight,

- high strength,

- excellent impact resistance,

- no white fiber,

- high translucency.

It can be used to manufacture lighting boards in building & construction industry.

| Product No. |

Linear Density, tex |

Product Features | Resin Compatibility | Applications | Data sheet |

|---|---|---|---|---|---|

| 872S | 2400,4800 | Low static; Moderate wet out; Excellent dispersion of the chopped strands under low tension | Unsaturated polyester, acrylic resin | Translucent and opaque panels | Download |

| 872 | 2400,4800 | Extremely fast wet-out; No white fiber; Superior transparency | Unsaturated polyester, acrylic resin | High transparency panel | Download |

| 838 | 2400,4800 | Low static; Fast wet out; No white fiber | Unsaturated polyester | General purpose transparent FRP panel | Download |

Direct Roving for LFT

Direct Roving for LFT is coated with a silane-based sizing compatible with PA, PBT, PET, PP, ABS, PPS and POM resins.

It is widely used in industries of automotive, electromechanical, home appliance, building & construction, electronic & electrical, and aerospace.

| Product No. |

Filament Diameter, um |

Resin Compatibility |

Applications | Data sheet |

|---|---|---|---|---|

| 362K | 17 | PP | Direct roving, excellent processing and mechanical property, extinct light color | Download |

| 352B | 17 | PA,TPU | Direct roving, excellent processing and mechanical property, designed for LFT-G process | Download |

| 362J | 16,17 | PP | Direct Roving, specially designed for LFT-D process and widely used in automotive,construction,sports,electric and electronic applications. | Download |

| 362G | 17 | PP | Direct Roving, speciall designed for LFT-D and LFT-G process | Download |

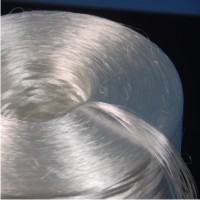

Direct Roving for weaving is compatible with unsaturated polyester, vinyl ester and epoxy resins.

Its excellent weaving property makes it suited for fiberglass product, such as roving cloth, combination mats, stitched mat, multi-axial fabric, geotextiles, molded grating.

The end-use products are widely used in building & construction, wind power and yacht applications.

| Product No. |

Nominal Linear Density, tex | Product Features | Resin Compatibility | Applications | Data sheet |

|---|---|---|---|---|---|

| 302 | 1200、2400 | Soft yarn; Low fuzz; Compatible with resins | Epoxy resin, Polyester | Suitable in manufacture of molded grating | Download |

| 306A | 800、900、1000、1200、1500、1700、2400、4800 | High strand strength; Low fuzz | Asphalt, | Suitable in manufacture of geotextiles, used to reinforce high-speed road | Download |

| 328 | 2000 | Compatible with epoxy resin, Fast wet out, Excellent mechanical property of the composite product, High modulus(particularly high tensile strength) | Epoxy resin | Suitable in manufacture of UD or multiaxial fabric, used as reinforcement of large wind energy blade by vacuum infusion process | Download |

| 396 | 300、600、735、1200、2000、2400 | Compatible with multiple resin system; Excellent mechanical properties of the composite product | Epoxy resin, Polyester | Suitable in manufacture of UD or multiaxial fabric, used as reinforcement of large wind energy blade by prepreg process | Download |

| 398 | 1200、2400 | Compatible with epoxy resin; Excellent weaving property; Excellent mechanical properties of the composite product; High modulus( particularly high compressive strength) | Epoxy resin | Suitable in manufacture of UD or multiaxial fabric used as reinforcement of large wind energy blade by vacuum infusion process | Download |

| 386T | 200、300、600、1200、2400、4800、9600 | Low fuzz; Excellent weaving property;Excellent mechanical property of the composite products | Unsaturated polyester | Suitable for manufacture of UD or multiaxial fabric used as reinforcement of large polyester wind energy blade | Download |

| 312 | 100、136、200、275、300 | Excellent weaving property; Excellent mechanical properties of the composite product | Unsaturated polyester, vinyl ester and epoxy resins | Suitable in manufacture of light weight roving cloth and multiaxial fabric | Download |

| 320 | 1200、2000、2400 | Compatible with multiple resin system; Excellent weaving property; Excellent mechanical properties of the composite product | Epoxy resin, Polyester | Suitable in manufacture of UD or multiaxial fabric, used as reinforcement of large wind energy blade by vacuum infusion process and prepreg process | Download |

| 386 | 200、300、600、1200、2400、4800、9600 | Compatible with matrix resins; Excellent mechanical properties of the composite product | Unsaturated polyester, vinyl ester and epoxy resins | Suitable in manufacture of roving cloth used as reinforcement for pipes, yachts | Download |

Direct Roving for Filament winding

Direct Roving for Filament winding, is compatible with unsaturated polyester, polyurethane, vinyl ester, epoxy and phenolic resins.

Main uses include manufacture of FRP pipes of various diameters, high-pressure pipes for petroleum transitions, pressure vessels, storage tanks, and, insulation materials such as utility rods and insulation tube.

| Product No. |

Nominal Linear Density, tex | Product Features | Resin Compatibility | Applications | Data sheet |

|---|---|---|---|---|---|

| 308 | 1200、2000、2400 | Compatible with epoxy resin, designed for filament winding process under high tension | Epoxy resin | Compatible with epoxy resin, used as reinforcement to manufacture high pressure pipe for petroleum transmission | Download |

| 396 | 2000 | Compatible with polyurethane; Excellent mechanical properties of the composite product | Polyurethane | Used to manufacture utility rods | Download |

| 386T | 200、300、600、1200、2400、4800、9600 | Compatible with resins; Low fuzz; Superior processing property; High mechanical strength of the composite product | Unsaturated polyester, vinyl ester, epoxy and phenolic resins | Used to manufacture storage tanks and medial-pressure FRP pipes for water transmission and chemical corrosion | Download |

| 310 | 1200、2400 | Excellent electrical property | Epoxy resin | Used to manufacture hollow insulation pipe | Download |

| 386 | 200、300、600、1200、2400、4800、9600 | Compatible with resins; Excellent mechanical properties of the composite product | Unsaturated polyester, vinyl ester and epoxy resins | Used to manufacture normal pressure-resistant FRP pipes and storage tanks | Download |

| 318 | 300、600、735、1200、2000、2400 | Compatible with epoxy resin; Low fuzz; Designed for filament winding process under low tension | Epoxy resin | Compatible with epoxy resin, used as reinforcement of pressure vessel and high- and medial- pressure resistance FRP pipe for water transmission | Download |

Direct Roving for Pultrusion

Direct Roving for Pultrusion is compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins, and is widely used in building & construction, telecommunication and insulator industry.

| Product No. |

Nominal Linear Density, tex | Product Features | Resin Compatibility | Applications | Data sheet |

|---|---|---|---|---|---|

| 310A | 2400、4800、9600 | Compatible with epoxy resin; Fast wet out; Excellent dielectrical and mechanical properties of the composite product | Epoxy resin | Used to manufacture insulator | Download |

| 316 | 300、600、1200 | Compatible with matrix resin; High tensile strength of the end composite product | Vinyl ester , | Used to manufacture optic cable | Download |

| 386T | 300、600、735、1200、2200、2400、4800、9600 | Compatible with matrix resin; Fast wet out; Eexcellent mechanical properties of the composite product | Unsaturated polyester, vinyl ester , epoxy | Used to manufacture various sectional bars | Download |

| 312 | 1200、2400、4400、4800、8800、9600 | Compatible with resins; Excellent mechanical properties of the composite product | Unsaturated polyester, vinyl ester and epoxy resins | Used to manufacture various sectional bars | Download |

| 312T | 2400、4400、4800、8800、9600 | Excellent tensile, flexural and shear properties for composites products | Unsaturated polyester, vinyl ester polyurathane and epoxy resins. | High performance pultruded profiles | Download |

E-Glass Emulsion Chopped Strand Mat

E-Glass Emulsion Chopped Strand Mat is made of randomly distributed chopped strands held tighter by a emulsion binder. It is compatible with UP, VE, EP resins.

he roll width ranges from 50mm to 1270mm. special requirements may be available upon request.

| Product No. |

Area Weigh(g/m2) |

Roll Width(mm) |

Resin Compatibility |

Product Features | Applications | Data sheet |

|---|---|---|---|---|---|---|

| E01 | 225, 300, 450, 600, 900 | 1040, 1270 | UP, VE, EP | High tensile strength, allowing for use in hand lay-up process to produce large-area parts; No airborne fiber when operating; Good wet-through and fast wet-out in resins, rapid air lease; High mechanical strength; Superior acid corrosion resistance | Hand lay-up | |

| E20 | 225, 300, 450, 600, 900 | 1040, 1270 | UP, VE, EP | Good conformability; Good wet-through and fast wet-out in resins, rapid air lease, reducing rolling out time and increasing productivity; Low resin consumption; High mechanical strength of the conposite product; Superior acid corrosion resistance | Hand lay-up |

E-Glass Powder Chopped Strand Mat

E-Glass Powder Chopped Strand Mat is made of randomly distributed chopped strands held together by a powder binder.

It is compatible with UP, VE, EP, PF resins.

The roll width ranges from 50mm to 3120mm.

Additional demands on wet-out and decomposition time may be available upon request.

| Product No. |

Area Weigh(g/m2) |

Roll Width(mm) |

Resin Compatibility |

Product Features | Applications | Data sheet |

|---|---|---|---|---|---|---|

| P10 | 100/110/135 | 1350/1680 | PU | High tensile strength, Insuring no breakage when unwinding; Uniform fiber glass content; Superior acid corrosion resistance | Automotive Headliner | Download |

| P20 | 225/300 /450/600/900 |

1040/1270 | UP,VE,EP | Soft mat, ease of manual tearing apart, good conformability; Good wet-through and fast wet-out in resins, rapid air release | Hand lay-up | Download |

| P02 | 225/300 /450/600/900 |

1040/1270 | UP,VE,EP | High tensile strength, suitable for use in hand lay-up process to produce large-area parts; Good wet-through and fast wet-out in resins, rapid air lease; High mechanical strength; Superior acid corrosion resistance | General Purpose | Download |

| P30 | 225/300 /450/600/900 |

1040/1270 | UP,VE,EP | Fast wet-out; Excellent translucency of the composite products; High mechanical strength; Superior acid corrosion resistance | Lighting boards, colors are available upon requests | Download |

| P04 | 225/300 /450/600/900 |

1040/1270 | UP,VE,EP | Fast breakdown in styrene,High tensile strength, allowing for use in hand lay-up process to produce large-area parts,Good wet-through and fast wet-out in resins, rapid air lease,High mechanical strength of parts,Superior acid corrosion resistance | General Purpose | Download |

Wet Chopped Strands

Wet Chopped Strands are compatible with unsaturated polyester, epoxy and phenolic resins and gypsum.

Wet Chopped Strands have moderate moisture content and deliver outstanding flowability, including dispersion in water and in gypsum.

E-Glass Texturized Roving

E-Glass Texturized Roving is compatible with PF, EP and UP resins.

It features as uniform texturizing and high absorbability; it is used to manufacture thermal insulation and acoustic insulation products.

| Product No. |

Nominal Linear Density, tex | Product Features | Resin Compatibility | Applications | Data sheet |

|---|---|---|---|---|---|

| 752 | 400、660、2400 | Excellent texturing process with optimum texturing efficiency; Compatible with multiple resins; Excellent mechanical properties of the composite product | UP/EP/PF | Automotive friction plate | Download |

| 756T | 4800/2400 | Fast and complete wet out; Good abrasion resistance and smooth transfer under high tension; Excellent mechanical properties of the composite products; Excellent fatigue resistance; Superior chemical corrosion resistance | EP/PF | Automotive muffler | Download |

High performance Compofil TM

CompofilTM is a high performance roving made of interwound continuous glass fiber and thermoplastic fiber. It can be used to manufacture thermoplastic composites directly with no need for extra resin. It is suitable for various molding processes including mold pressing, vacuum molding, filament winding and more. The applications of this product include Military, automotive, construction, sports and new energy industries.

| Product No. | Data sheet |

|---|---|

| Compofil-PET,Compofil-PPS,Compofil-PP,Compofil-fabric | Download |

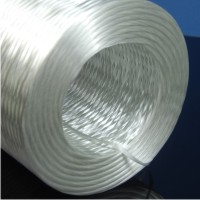

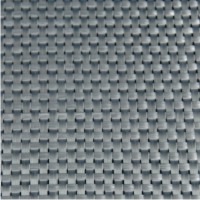

Woven roving

E-Glass Woven Rovings are bidirectional fabric made by interweaving direct rovings.

E-Glass Woven Rovings are compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

E-Glass Woven Rovings are a high-performance reinforcement widely used in hand lay up and robot processes to manufacture boats, vessels, plane and automotive parts, furniture and sports facilities.

| Area Weight (g/m2) | Width (mm) | Data sheet |

|---|---|---|

| 200 ~ 1600 | 50 ~ 3000 | Download |

Chopped Stands for Thermoplastics

Chopped Stands for Thermoplastic are based on silane coupling agent and special sizing formulation, compatible with PA,PBT/PET, PP, AS/ABS, PC, PPS/PPO,POM, LCP;

E-Glass Chopped Stands for thermoplastic are know for excellent strand integrity, superior flowability and processing property, delivering excellent mechanical property and high surface quality to its finished product.

| Resin Compatibility |

Product No. |

Certification | Product Features | Data sheet |

|---|---|---|---|---|

| PA6/PA66/PA46 | 560A | FDA | Standard product | Download |

| PA6/PA66/PA46 | 568H | FDA | Excellent glycol resistance | Download |

| HTN/PPA | 560H | / | Super high temperature resistance, extremely low out-gassing, for PA6T/PA9T/PA10T, etc. | Download |

| PBT/PET | 534A | FDA | Standard product | Download |

| PBT/PET | 534W | / | Excellent color of composite parts | Download |

| PBT/PET | 534V | / | Excellent hydrolysis resistance | Download |

| PP/PE | 508A | FDA | Standard product, good color | Download |

| ABS/AS/PS | 526 | / | Standard product | Download |

| m-PPO | 540 | FDA | Standard product, extremely low out-gassing | Download |

| PPS | 584 | / | Excellent hydrolysis resistance | Download |

| PC | 510 | FDA | Standard product, excellent mechanical properties, good color | Download |

| PC | 510H | / | Super high impact properties, glass content below 15% by weight | Download |

| POM | 500 | / | Standard product | Download |

| LCP | 542 | / | Excellent mechanical properties and extremely low out-gassing | Download |

| PP/PE | 508H | / | Excellent detergent resistance | Download |

Chopped Strands for BMC

Chopped Strands for BMC are compatible with unsaturated polyester, epoxy resin and phenolic resins.

The end-use applications include transportation, building & construction, electronic & electrical, mechanical, and light industry.

| Product No. |

Nominal Chopped Length(mm) |

Product Features | Resin Compatibility |

Applications | Data sheet |

|---|---|---|---|---|---|

| 562E | 3,6,9,12,18,24 | Extremely low resin demand, delivering low viscosity to BMC paste | Unsaturated polyester, vinyl ester and epoxy resins | Suitable to manufacture high fiberglass loading products with complex structure and superior color, for example, ceiling tiles and lampshade. | Download |

| 588 | 3,6,9,12,18,24 | High strand stiffness; Compatible with rubber | Rubber | Used to manufacture products with superior friction coefficient, including tire | Download |

| 552B | 3,6,9,12,18,24 | High impact strength; High LOI rate | Unsaturated polyester, vinyl ester and epoxy resins | Used in automotive parts, civilian electrical switches, sanitary ware and other products requiring high strength. | Download |

| 558 | 13 | Good strand integrity,low static and fuzz, Fast and uniform distribution in resins,excellent mechanical and processing properties | Phenolic resin | Used to manufacture various brake shoe facings, clutch facings, and friction plates. | Download |